Improvement of indoor air quality is one of the significant missions of air conditioner. To bring the encompassing natural air into the structure is a biological and powerful arrangement which is obligatory to control indoor CO2 level and solace. Amrta air to air HR system offers a parfait energy recovery solution by absorbing heat from the fumes air so as to pre-treat the fresh air to achieve at the same time:

- An high performance of the improvement of indoor air quality and comfort.

- An economical operation for remarkable energy saving.

Two types of HR gear are accessible as indicated by the venture necessity: Plate heat exchanger or Wheel heat exchanger. Despite the fact that the utilization of the HR framework perhaps increment some of vitality utilization of fans, however the advantage of vitality sparing will be assurance more noteworthy than that. The test information demonstrate that the presentation of warmth recuperation can be up to 70% for recuperation productivity and 100% for volume of fumes air.

The HR framework is currently broadly applied in private, business, mechanical applications. Basically, applications which request the greater air and outside air rate are emphatically suggested.

Structure

Boards and edge are produced using electrifies steel secured with polyester powder painting to guarantee complete protection from climatic operators.

Direct development curls with condensate channel plate.

Hermetic scroll compressor

High efficiency scroll compressor for the entire range, with built-in thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers.

Ripple type acoustic insulation for compressor section, and thermal insulation for coil and fan section, low noise.

Centrifugal fan

Forward bend radial fans for air treatment area and axial fans for condensation section

Front, side and underside air discharge of the treatment unit.

High external pressure, long air supply distance.

Electric board

Electric board comprises of breakers and contactors for blowers and fan engines, stage succession transfer and other important security gadgets for the fundamental parts.

Easy operation line controller

Cooling/Heating/Auto

Mistake sign

Timing on/off

Optional

Economizer with new, return air dampers and fresh air hood

Free cooling function for low ambient temperature

Low ambient control device for operation of outdoor units at ambient temperatures from under 20°C down to - 10°C

BMS devices

T3 (Tropical climate)

Roof curb

Metal/aluminum filter

100% heat recovery

Evaporating section: double skin with 50mm polyurethane foam

Optional water heating coil

Metal or plastic mesh on condenser coil

Optional supply/return air configurations

Updated plug fan

G4 filter, plate and bag filter

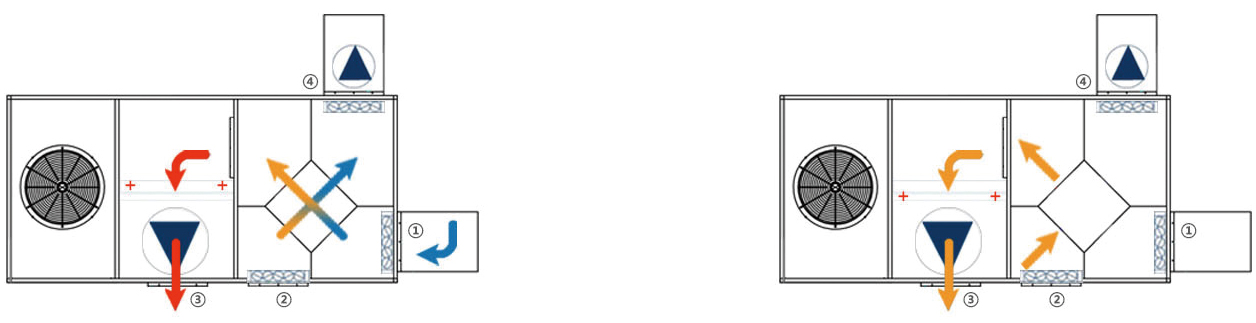

Heat recovery diagram

Plate heat recovery

Heating mode Recyling mode

Cooling mode

①Fresh air ②Return air ③Supply air ④Exhaust air

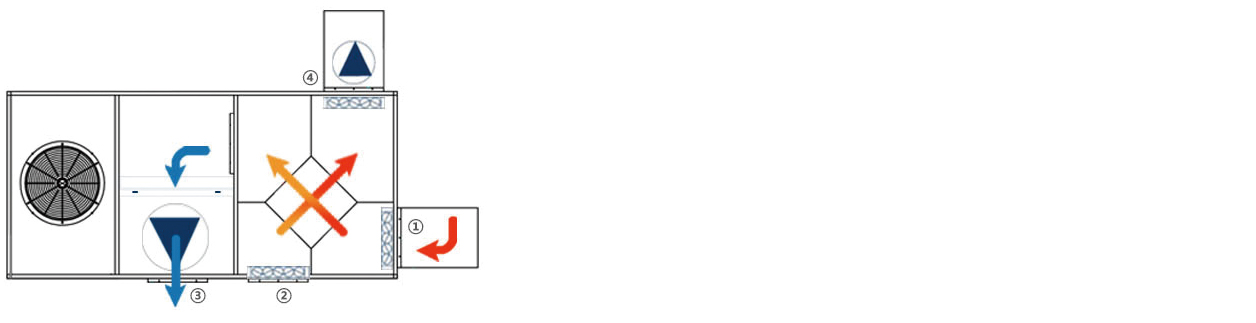

Wheel heat recovery

Heating mode Recyling mode

Cooling mode

①Fresh air ②Return air ③Supply air ④Exhaust air(optional)

Note: For downflow only, otherwise it will be different structure

Technical Data

* Performance values refer to the following conditions:

Cooling: room air temperature 27.0°C DB RH 50%, ambient air temperature 35°C.

Heating: room air temperature 21.0°C DB, ambient air temperature 7°C DB / 6°C WB.

** Noise level measured by adopting average value in the noise lab with background noise of 25 dB(A), at a distance of 1.5m high fan speed.